Standard Specifications and Variations

Standard Product

Weather resistant / indicator type

Separated type

Changeable Heads

List of Options

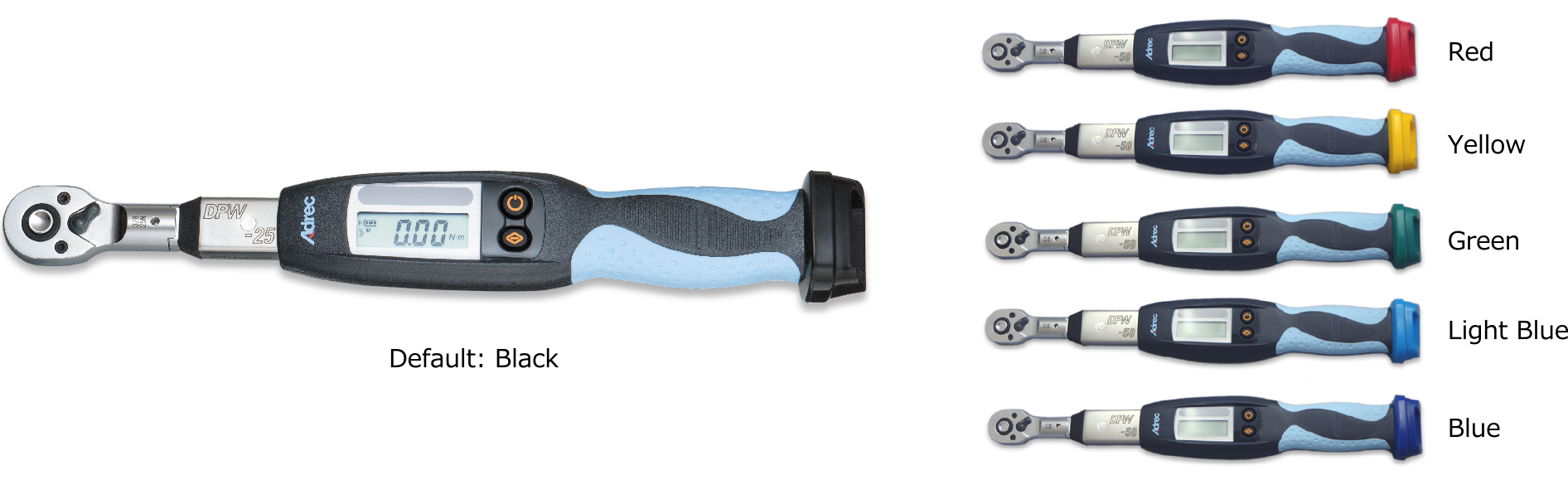

Colors

There are 6 colors in total to choose from.

Black is standard, but if you wish to get another color, please let us know at the time of ordering.

The grip end can also be purchased individually. The size differs for each wrench, so please let us know your wrench size when you order.

| Name | Supported torque wrenches |

| Grip end (S) | DPW-10、DPW-25 |

| Grip end (M) | DPW-50、DPW-100、DPW-150 |

| Grip end (L) | DPW-200、DPW-300、DPW-400、DPW-600、DPW-800 |

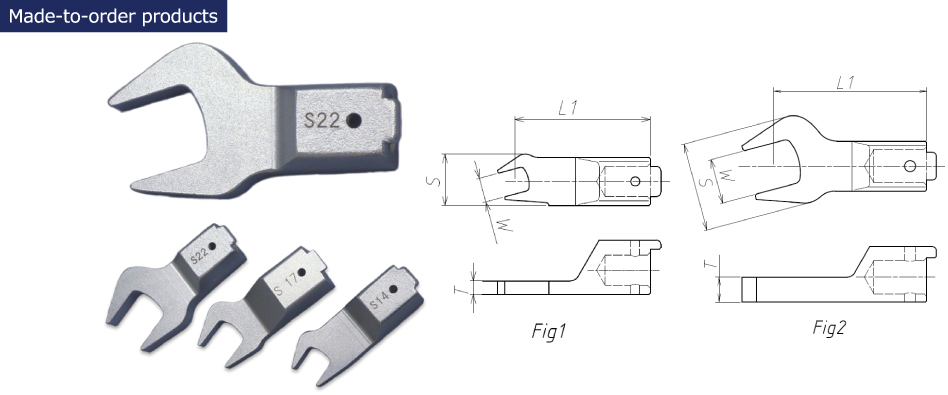

Changeable Heads

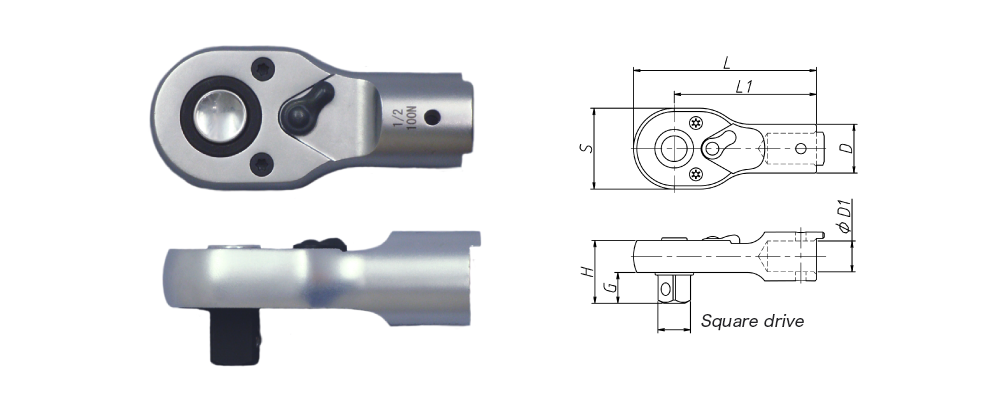

Ratchet Heads

| Model | Square drive | Rachet gear tooth count | S | H | G | D | L1 | φD1 | L | Applicable torque wrenches |

| QPH10 | 6.35(1/4) | 72 | 25 | 17.5 | 8 | 16 | 45 | 10 | 57.5 | DPW10 |

| QPH25 | 9.53(3/8) | 72 | 32 | 25.5 | 12 | 19 | 50 | 10 | 66 | DPW25 |

| QPH50 | 9.53(3/8) | 72 | 32 | 25.5 | 12 | 19 | 55 | 12 | 71 | DPW50 |

| QPH100 | 12.7(1/2) | 72 | 39 | 33 | 16 | 26 | 65 | 15 | 84 | DPW100 |

| QPH200 | 12.7(1/2) | 72 | 39 | 33 | 16 | 26 | 80 | 18 | 99.5 | DPW150 DPW200 |

| QCH400 | 19.0(3/4) | 24 | 54 | 43 | 20 | 30 | 100 | 22 | 127 | DPW300 DPW400 |

| QCH600 | 19.0(3/4) | 24 | 68 | 49.5 | 20 | 41 | 125 | 30 | 160 | DPW600 |

| QCH1000 | 25.4(1) | 24 | 76 | 58 | 27 | 45 | 130 | 34 | 168 | DPW850 |

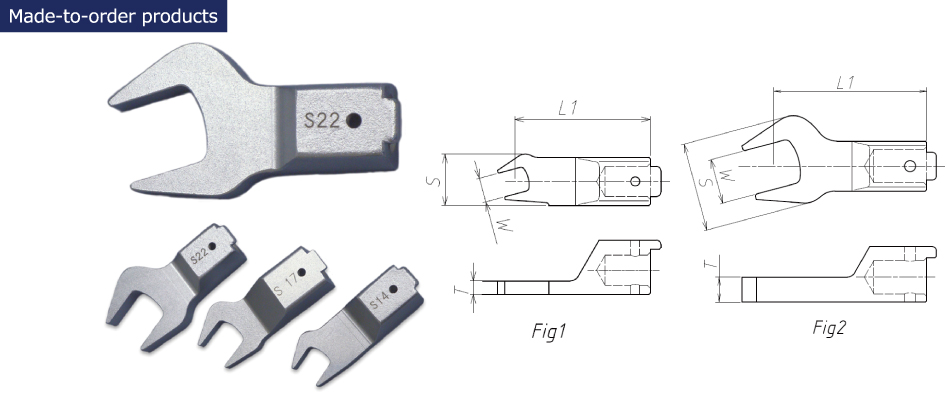

Spanner Heads

| Model | Mouth width W | S | T | Mouth width W | S | T | L1 | φD1 | D2 | L | Applicable torque wrenches |

| SPH10 | 5.5 | 11 | 4.5 | 13 | 26 | 7 | 45 | 10 | 16 | (49)~(60) | DPW10 |

| 6 | 12 | 14 | 28 | ||||||||

| 7 | 14 | 16 | 32 | ||||||||

| 8 | 16 | 17 | 34 | ||||||||

| 9 | 18 | 18 | 36 | ||||||||

| 10 | 20 | 7 | 19 | 38 | 9 | ||||||

| 11 | 22 | 21 | 42 | ||||||||

| 12 | 24 | ||||||||||

| SPH25 | 5.5 | 11 | 4.5 | 13 | 26 | 7 | 50 | 10 | 16 | (54)~(65) | DPW25 |

| 6 | 12 | 14 | 28 | ||||||||

| 7 | 14 | 16 | 32 | ||||||||

| 8 | 16 | 17 | 34 | ||||||||

| 9 | 18 | 18 | 36 | ||||||||

| 10 | 20 | 7 | 19 | 38 | 9 | ||||||

| 11 | 22 | 21 | 42 | ||||||||

| 12 | 24 | ||||||||||

| SPH50 | 9 | 18 | 7 | 17 | 34 | 9 | 55 | 12 | 18 | (62)~(74) | DPW50 |

| 10 | 20 | 18 | 36 | ||||||||

| 11 | 22 | 19 | 38 | ||||||||

| 12 | 24 | 21 | 42 | ||||||||

| 13 | 26 | 22 | 44 | ||||||||

| 14 | 28 | 24 | 48 | 12 | |||||||

| 16 | 32 | 9 | 27 | 54 | |||||||

| SPH100 | 12 | 24 | 8 | 21 | 42 | 12 | 65 | 15 | 24 | (74)~(88) | DPW100 |

| 13 | 26 | 22 | 44 | ||||||||

| 14 | 28 | 24 | 48 | ||||||||

| 16 | 32 | 27 | 54 | ||||||||

| 17 | 34 | 30 | 60 | 14 | |||||||

| 18 | 36 | 32 | 64 | ||||||||

| 19 | 38 | ||||||||||

| SPH200 | 17 | 34 | 10 | 27 | 56 | 12 | 80 | 18 | 26 | (92)~(110) | DPW150 DPW200 |

| 18 | 36 | 30 | 62 | ||||||||

| 19 | 38 | 32 | 66 | ||||||||

| 21 | 44 | 36 | 74 | 15 | |||||||

| 22 | 48 | 41 | 84 | ||||||||

| 24 | 50 | 12 | |||||||||

| SCH400 ※Shared with HTWC |

17 | 34 | 12 | 29 | 58 | 15 | 100 | 22 | 32 | (115)~(136) | DPW300 DPW400 |

| 18 | 36.5 | 30 | 60 | ||||||||

| 19 | 38.5 | 32 | 72 | ||||||||

| 21 | 42 | 34 | 78 | ||||||||

| 22 | 44 | 36 | 72 | ||||||||

| 23 | 46 | 38 | 76 | ||||||||

| 24 | 48 | 41 | 82 | 17 | |||||||

| 26 | 52 | 46 | 92 | ||||||||

| 27 | 60 | 50 | 100 |

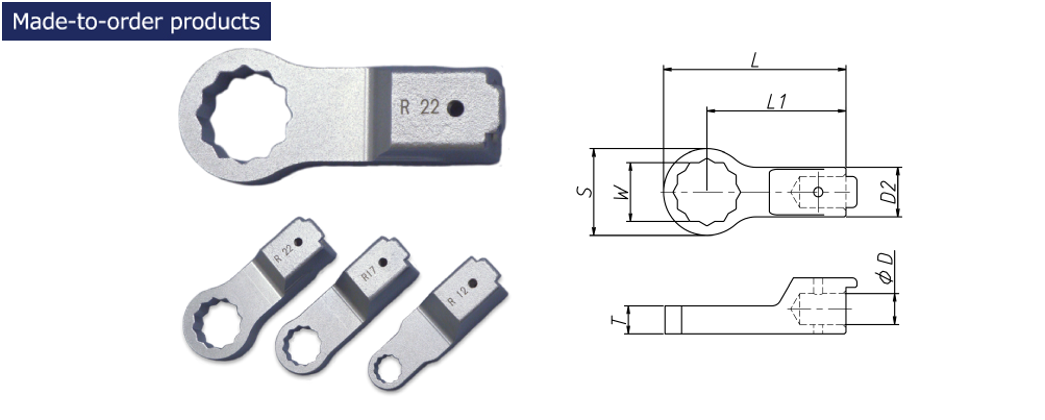

Spectacle Heads

| Model | Mouth width W | S | T | L1 | φD1 | D2 | L | Applicable torque wrenches | ||

| RPH10 | 6 | 7 | 8 | 13~16 | 4.5 | 45 | 10 | 16 | (54)~(61) | DPW10 |

| 9 | ||||||||||

| 10 | 11 | 12 | 18~21 | 7 | ||||||

| 13 | ||||||||||

| 14 | 17 | 22~26 | ||||||||

| 19 | 22 | 28~35 | 9 | |||||||

| RPH25 | 6 | 7 | 8 | 13~16 | 4.5 | 50 | 10 | 16 | (59)~(66) | DPW25 |

| 9 | ||||||||||

| 10 | 11 | 12 | 18~21 | 7 | ||||||

| 13 | ||||||||||

| 14 | 17 | 22~26 | ||||||||

| 19 | 22 | 28~35 | 9 | |||||||

| RPH50 | 8 | 10 | 11 | 15~18 | 7 | 55 | 12 | 18 | (65)~(71) | DPW50 |

| 12 | 13 | 14 | 19~22 | |||||||

| 17 | 19 | 22 | 26~35 | 9 | ||||||

| 24 | 27 | 35~40 | 12 | |||||||

| RPH100 | 12 | 13 | 14 | 19~22 | 8 | 65 | 15 | 24 | (78)~(86) | DPW100 |

| 17 | 19 | 26~30 | ||||||||

| 22 | 24 | 27 | 35~42 | 12 | ||||||

| 30 | 32 | 47~50 | 14 | |||||||

| RPH200 | 17 | 19 | 22 | 26~35 | 10 | 80 | 18 | 26 | (98)~(110) | DPW150 DPW200 |

| 24 | 27 | 30 | 38~50 | 12 | ||||||

| 32 | ||||||||||

| 36 | 41 | 56~65 | 15 | |||||||

| RCH400 *Shared with HTWC |

17 | 19 | 22 | 26~35 | 12 | 100 | 22 | 32 | (115)~(136) | DPW300 DPW400 |

| 24 | 27 | 38~42 | ||||||||

| 30 | 32 | 36 | 47~56 | 15 | ||||||

| 41 | 46 | 50 | 65~80 | 17 | ||||||

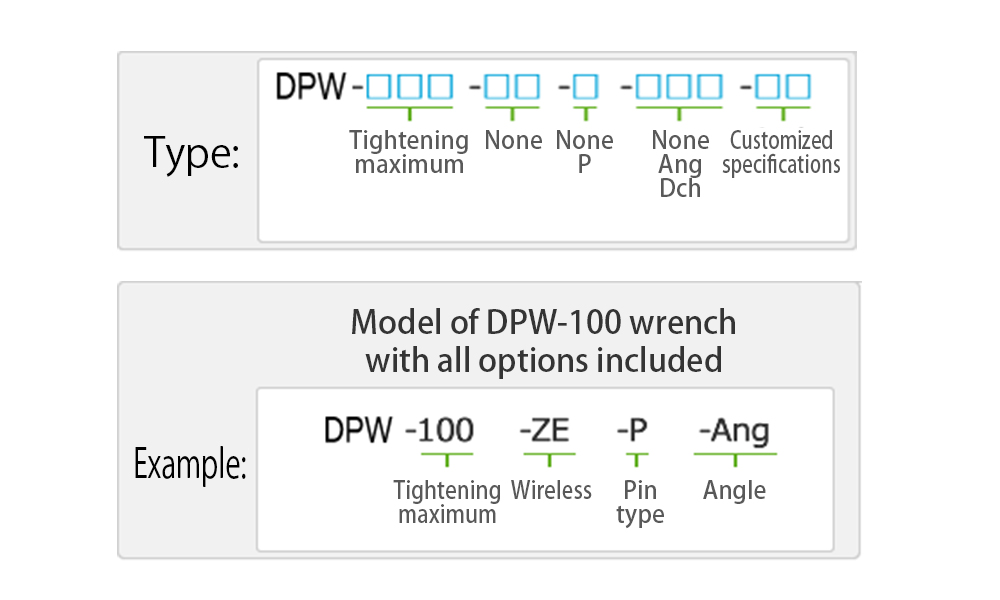

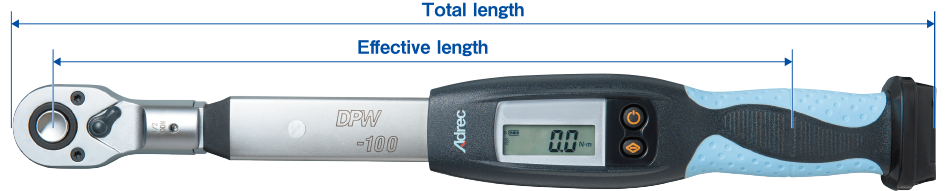

List of Options

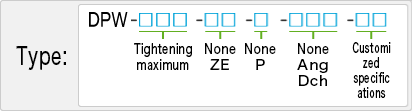

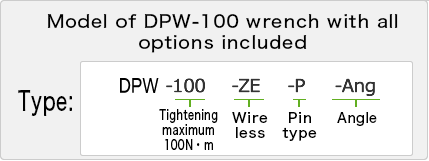

Model function description (Not weather resistant)

Features such as pin type, angle functions, and wired/wireless are indicated by the model number

| Model | Wireless | Pin type | Angle | Customized software |

| DPW | None : Wired ZE : Wireless |

None P:Pin type |

None Ang:Angle Dch : Retightening |

Options support table

| Model | -ZE Wireless |

-P Pin type (Free of charge) |

-Ang With angle calibration |

-Dch Without angle calibration Retightening prevention & screw-tightening inspection |

| DPW-10 | ○ | ○ | ○ | ○ |

| DPW-25 | ○ | ○ | ○ | ○ |

| DPW-50 | ○ | ○ | ○ | ○ |

| DPW-100 | ○ | ○ | ○ | ○ |

| DPW-200 | ○ | ○ | ○ | ○ |

| DPW-300 | ○ | × | ○ | ○ |

| DPW-400 | ○ | × | ○ | ○ |

| DPW-600 | ○ | × | ○ | ○ |

| DPW-850 | ○ | × | ○ | ○ |

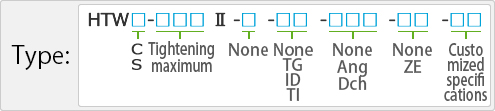

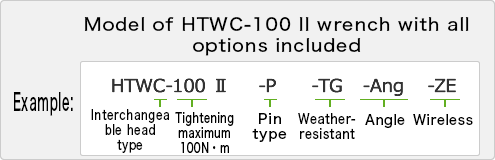

Model function description (Weather resistant)

| Model | Pin type | Weather resistant | Angle | Wireless | Customized software |

| HTWC / HTWS | None P:Pin type |

None TG : Weather resistant ID : Indicator TI : Weather resistant indicator |

None Ang:Angle Dch : Retightening |

None : Wired ZE:Wireless |

Options support table

| Model | -P Pin type (Free of charge) |

-TG Weather resistant [IPX6] |

-ID Indicator |

-TI Weather resistant・Indicator |

-Ang With angle calibration |

-Dch Without angle calibration Retightening prevention & screw-tightening inspection |

-ZE Wireless |

| HTWS-1.5Ⅱ | ◯ | × | × | × | × | × | ◯ |

| HTWS-3.0Ⅱ | ◯ | × | × | × | × | × | ◯ |

| HTWS-5.0Ⅱ | ◯ | × | × | × | × | × | ◯ |

| HTWC-50Ⅱ | ◯ | ◯ | × | × | ◯ | ◯ | ◯ |

| HTWC-100Ⅱ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| HTWC-200Ⅱ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| HTWC-300Ⅱ | × | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| HTWC-400Ⅱ | × | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

| HTWC-600Ⅱ | × | ◯ | ◯ | ◯ | ◯ | ◯ | ◯ |

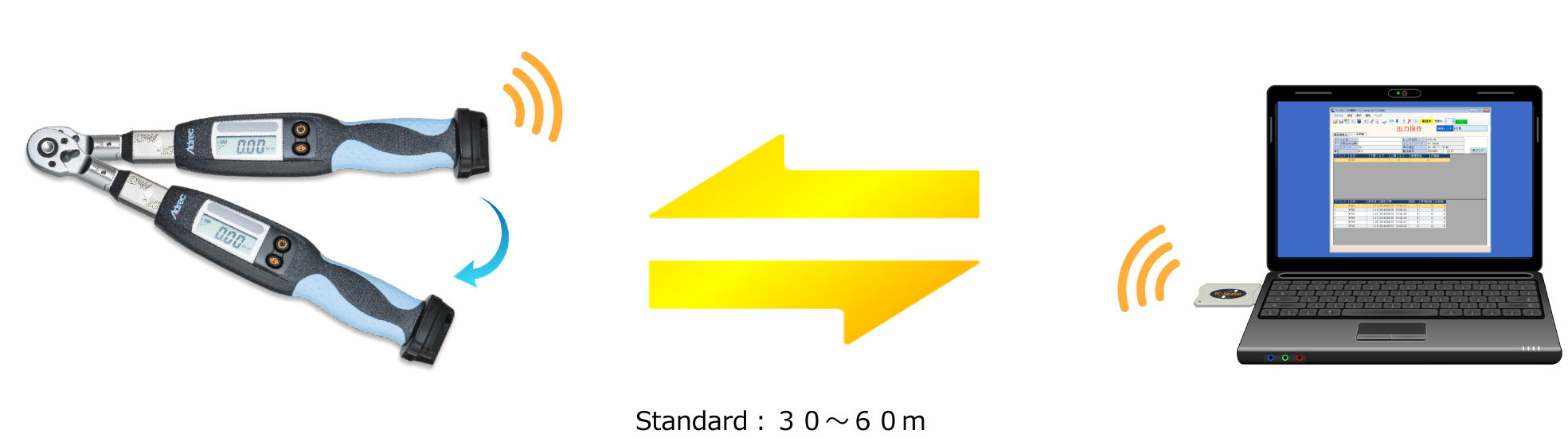

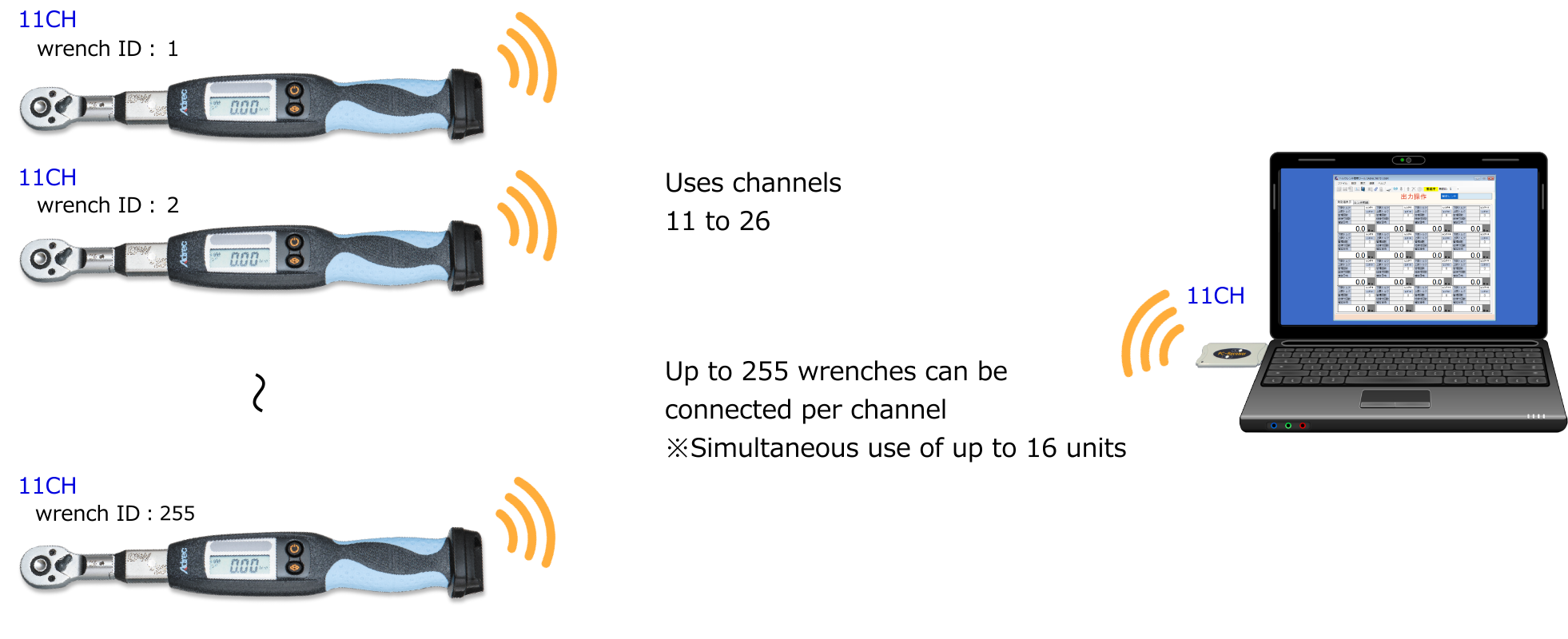

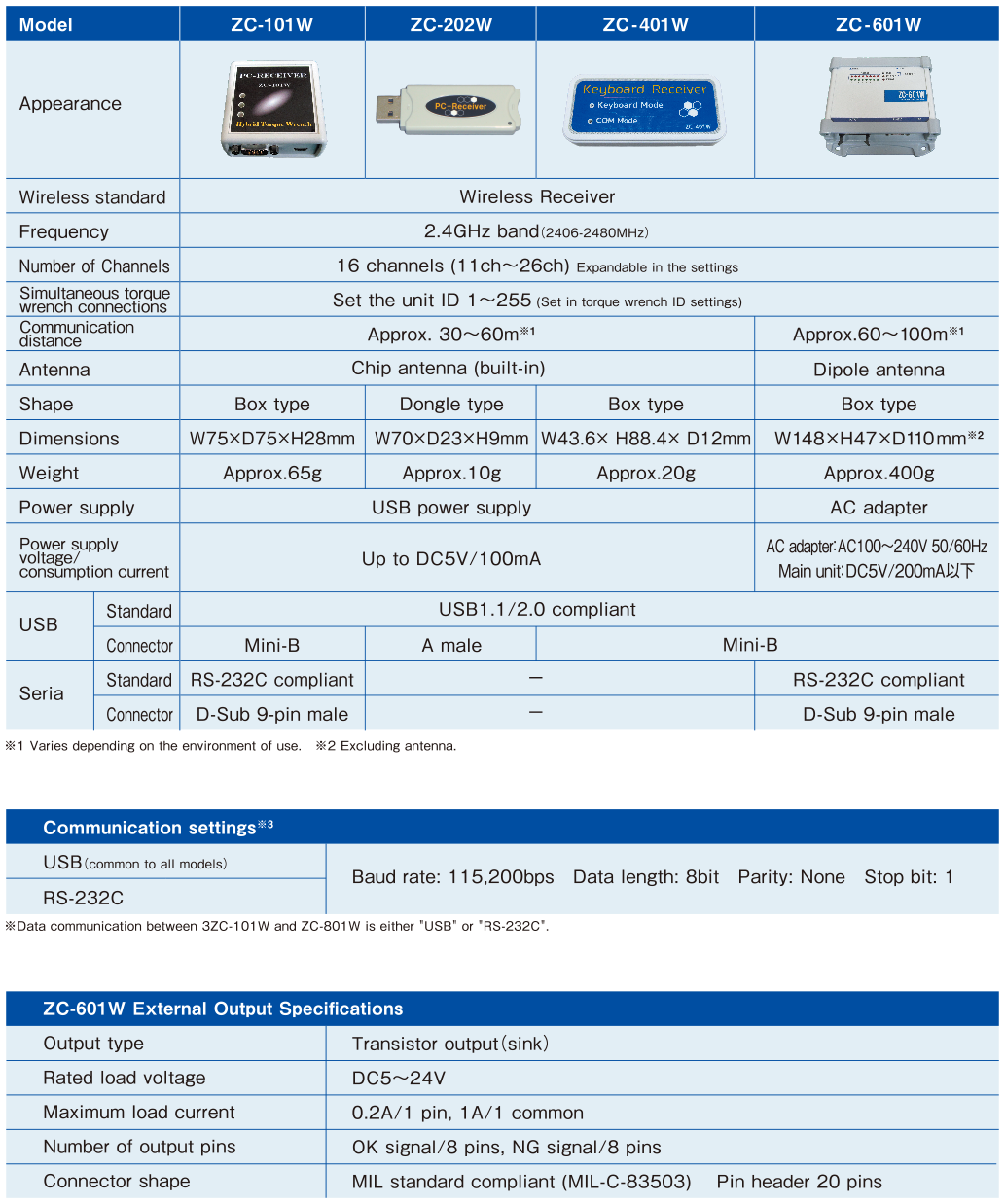

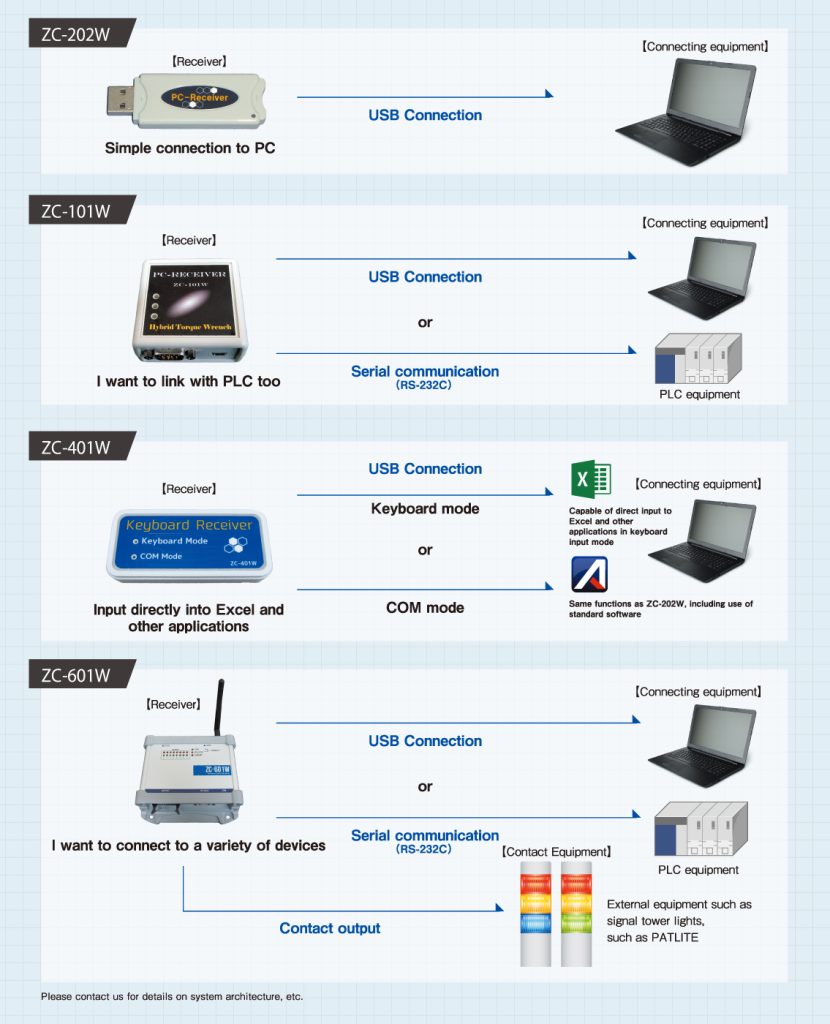

Wireless Specifications

Communication range: 30-60 m

One receiver can connect to 255 torque wrenches

Wireless Specifications/Model:DPW-***-ZE

Various types of receivers are available for different use cases!

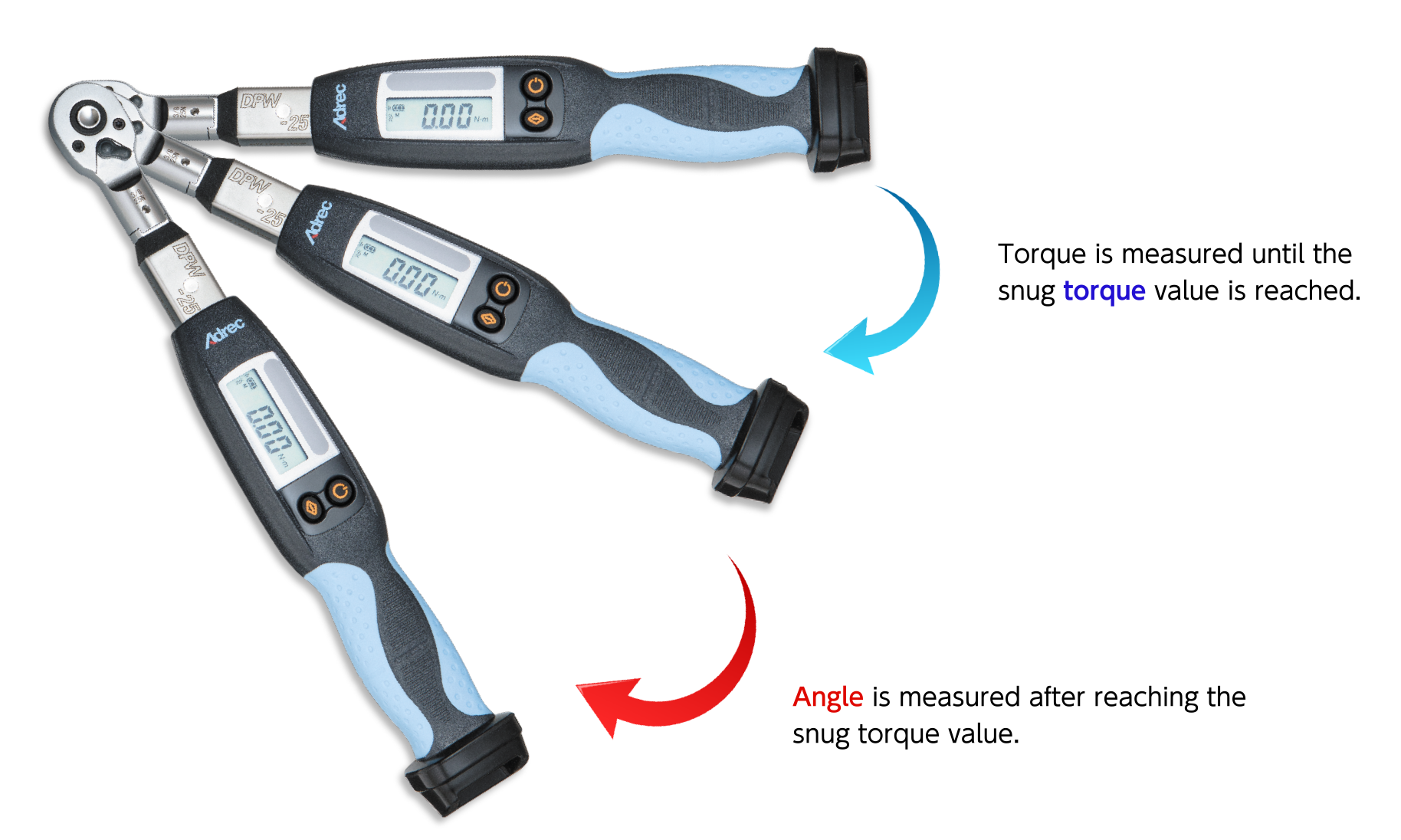

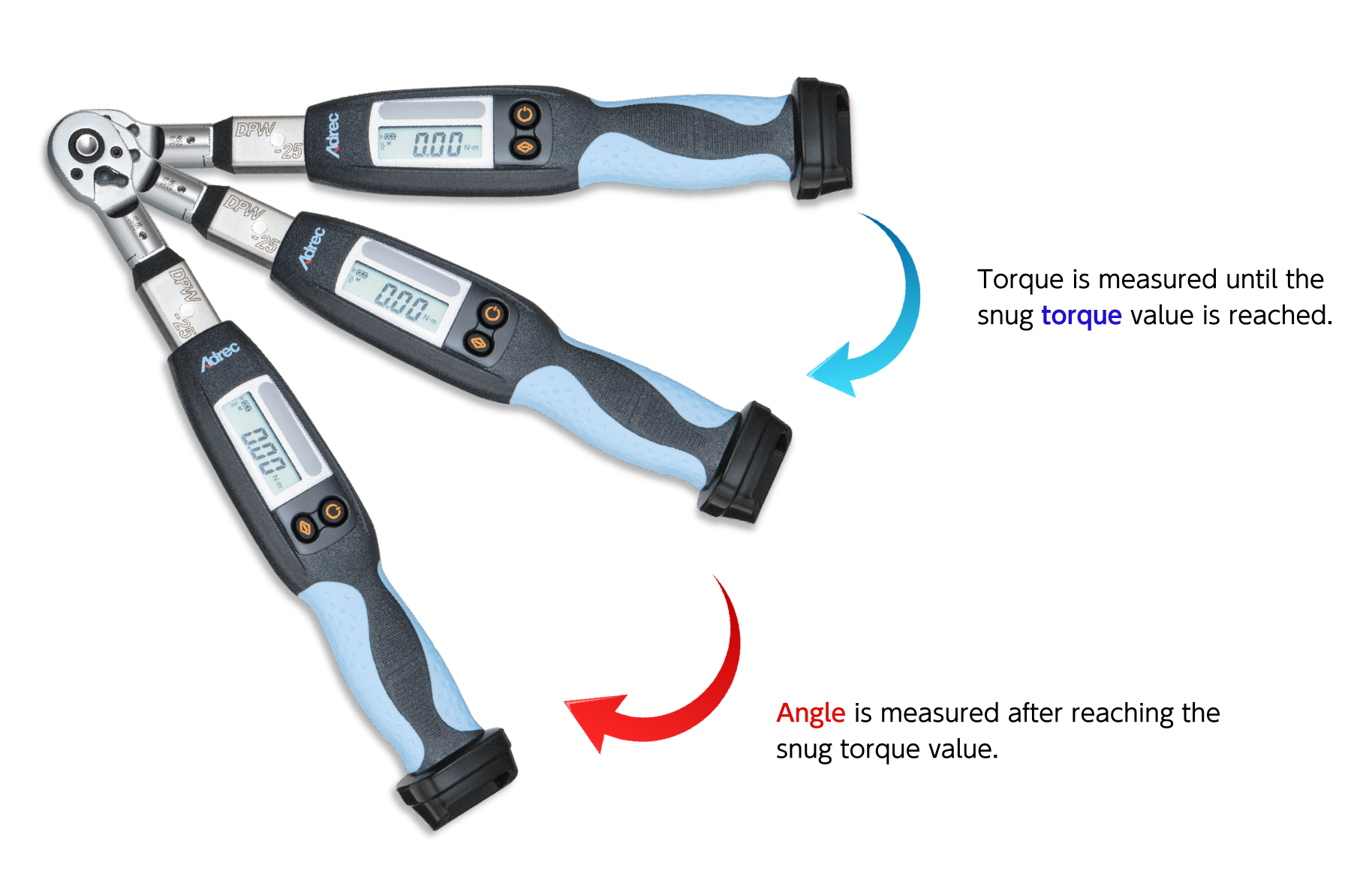

Angle Calibration Option

Our digital angle wrench for both torque & rotation angle methods

A digital angle wrench is a compound type wrench that supports both torque method & rotation angle methods through software inside the torque wrench.

When "torque data" is set in the software, the wrench can be used as a conventional torque wrench, and when "angle data" is set, the wrench can be used as an angle wrench with to the rotation angle methods.

Feature Descriptions

・Set the snug torque, and lower and upper angle limits.

・When the snug torque is reached, angle measurement starts.

・Peak angle and the torque value at that time are recorded.

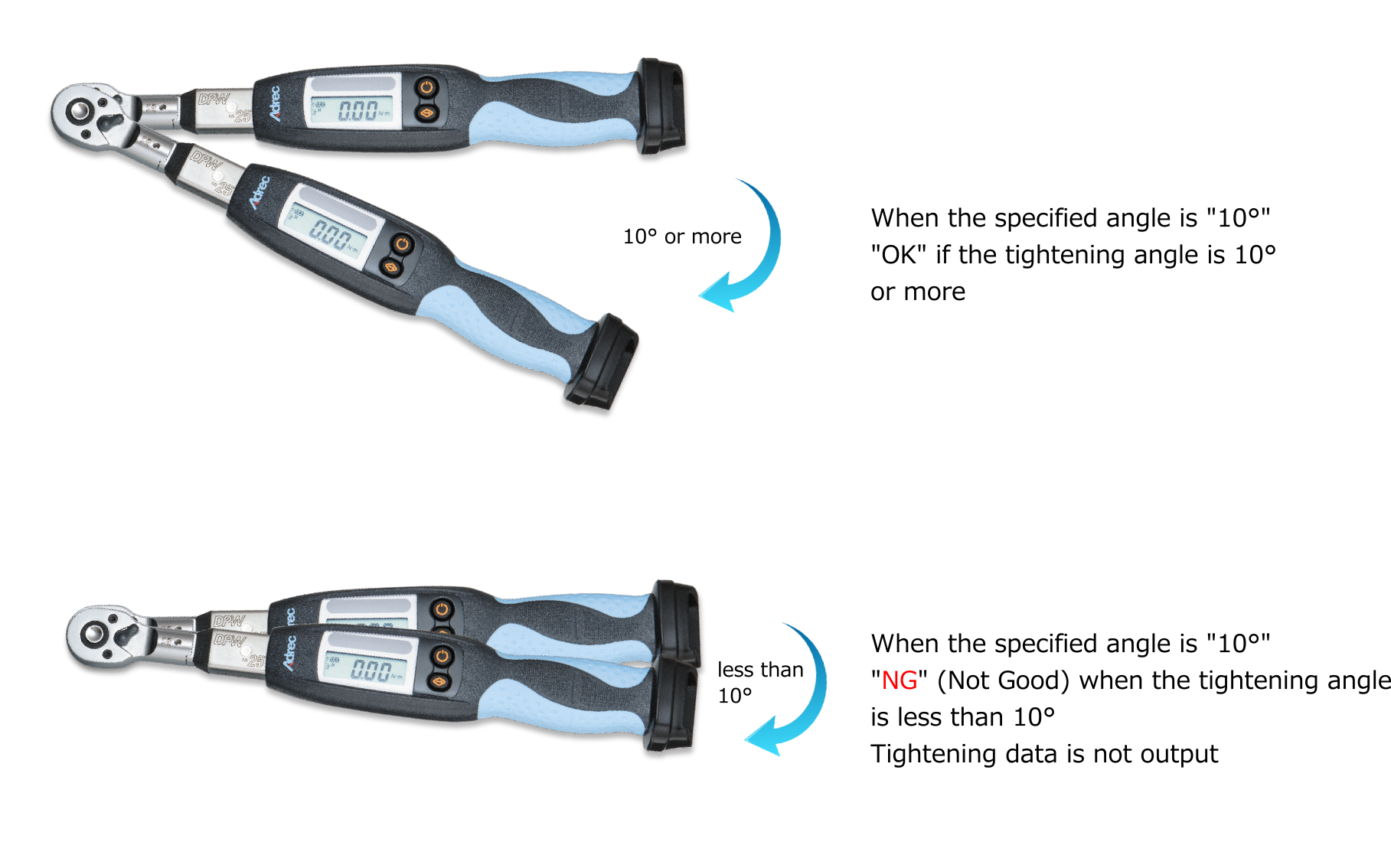

Retightening prevention feature

If a screw that has already been tightened to the specified torque is about to be re-tightened, retightening is prevented through monitoring the increase in torque and the angle of movement of the torque wrench.

・Set the specified angle, and lower and upper torque limits.

・Angle measurement starts at 10% of the lower torque limit.

・There is an error warning if the angle at peak torque is less than the specified angle (when retightening a screw that has already been tightened).

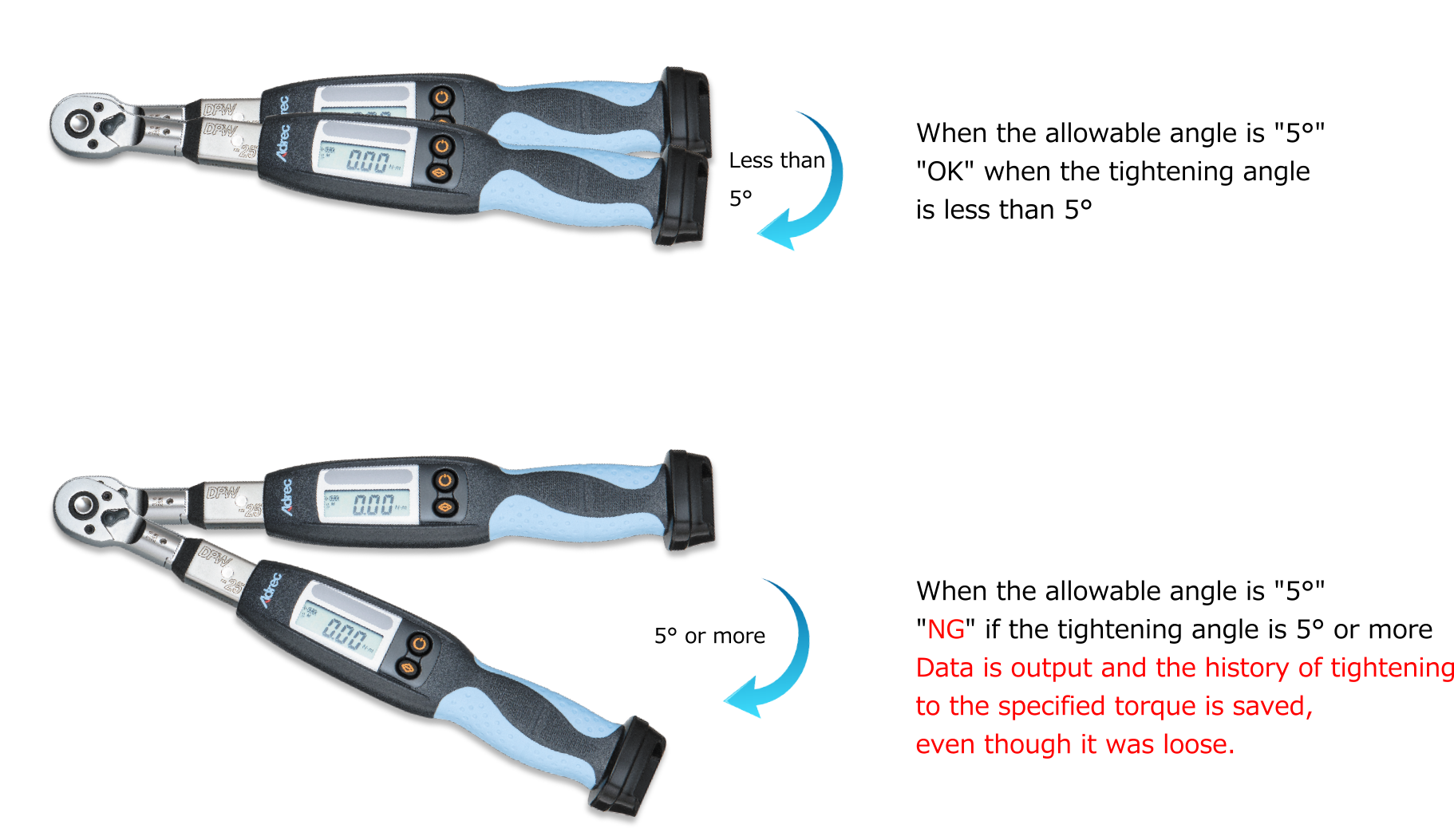

Screw-tightening inspection feature

The "retightening prevention" function is applied to determine whether a screw is properly tight or too loose by retightening the screw to a specified torque and monitoring the torque and angle.

・Set the allowable angle, and lower and upper torque limits.

・Angle measurement starts at 10% of the lower torque limit.

・There is an error warning if the angle at peak torque exceeds an allowable angle

| Details | No angle calibration (Retightening/Screw inspection specifications) | With angle calibration |

| Model | DPW-***-Dch | DPW-***-Ang |

| Functions/Model | DPW (Changeable head type) | ← |

| Measurement direction | Clockwise/Counterclockwise, both left and right (Switchable to one direction (Clockwise)) | ← |

| Measurement range | 1°~6000° | ← |

| Angular resolution | 0.1° | ← |

| Angular accuracy | No angle calibration | ±2° + 1 digit Provided that the rotation has a rotational angular velocity within 10°/s to 120°/s. |

| Torque setting range (snug) | Angle wrench specification: 5% - 100% (maximum torque value) Real-time monitor specification: 1% to 100% (maximum torque value) |

← |

| Angle setting range | 1°~6000° | ← |

| Angle measurement split function (Interval timer) |

When using the interval timer, split measurements can be made using the ratchet function. To note, the final angle accuracy will be based on the split data, and the result will be the accumulation of the split data. |

← |