How to use each option

Options

Option 1: Angle measurement function

A gyroscopic sensor is mounted on the unit of the torque wrench in order to measure angles.

Can be used for tightening with the rotary angle method and retightening detection.

The angle measurement option has a choice of calibration or no calibration

- Angle calibration (Ang) : Angular accuracy of ±2% is guaranteed.

- No angle calibration (Dch) : Angular accuracy is not guaranteed but this is not a problem if being used with retightening prevention and screw-tightening inspection.

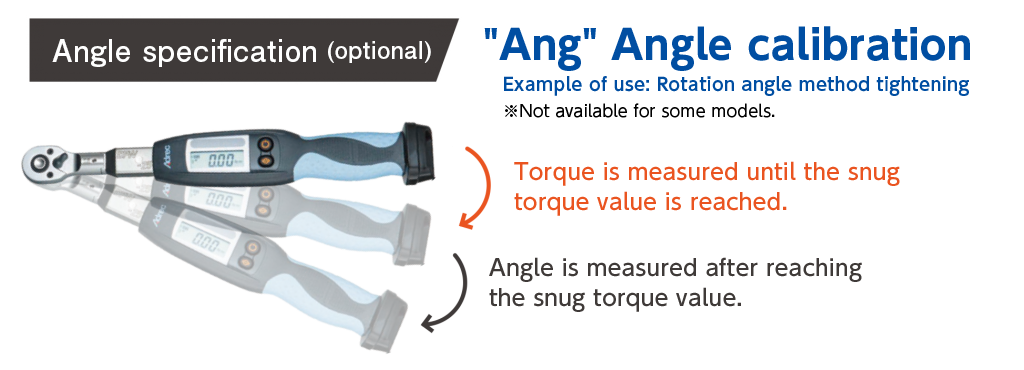

Angle calibration (Angle accuracy ±2% guaranteed)

In the rotary angle method mode, angle measurement starts when the set seating torque (snug torque) value is reached. The peak angle is determined by the set lower and upper limit angles. It is used in various engine assemblies, among other applications.

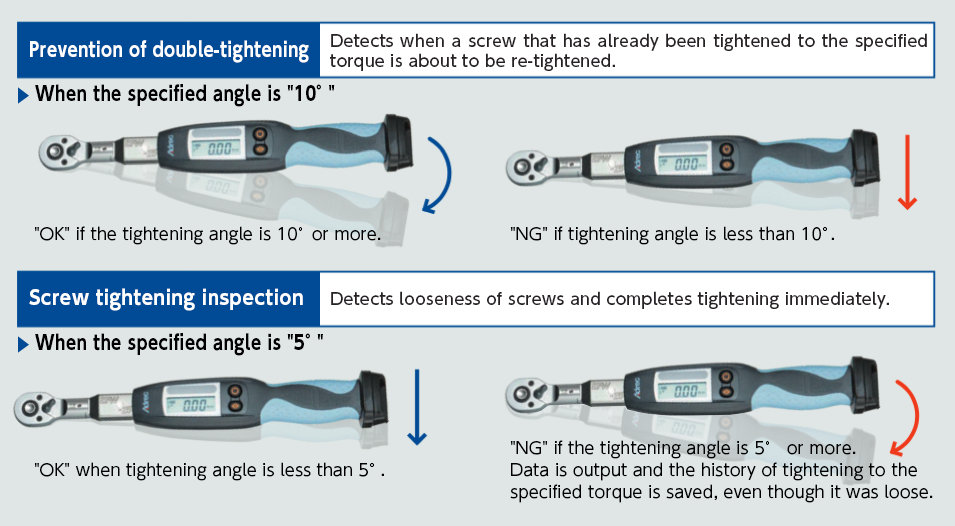

No angle calibration

In retightening prevention and screw-tightening inspection modes, the angle measurement starts from 10% of the lower torque limit of the measured torque value. Judgement of both torque and angle isperformed at peak torque.

The retightening prevention is used as a fail-safe during assembly work, and screw-tightening inspection is used for equipment inspections, etc.

Option 2: Weather resistance

IPX6 = Protection against jets of water at high pressures. Work can be done outdoors in the rain.

It can be used, for example, in railroad maintenance work or solar panel installation work.

*Cannot be submerged in water

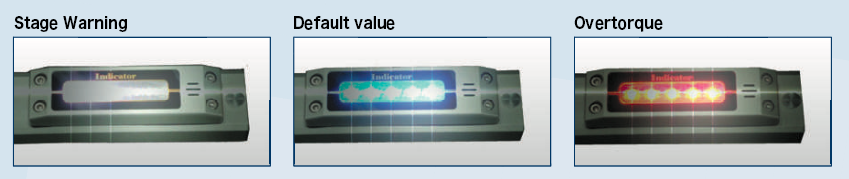

Option 3: Indicator

Even when working in the dark, the tightening result is clearly shown on an easy-to-understand indicator, preventing anything from overlooked or missed. The sound is also louder than normal.

Customers who are considering purchasing

Please contact us before purchasing!

Many companies have already adopted our products and are using them in a wide variety of ways.

Please contact us first and we will create the optimal proposal for your company.

Online consultations are also available.